How To Adjust A TXV Valve For Optimal HVAC Performance

Can You Adjust A Txv Valve is the process of altering the operation of a thermal expansion valve (TXV) to regulate the flow of refrigerant in a refrigeration system. TXVs are essential components in refrigeration and air conditioning systems, used to control the flow of refrigerant based on the temperature of the evaporator, ensuring optimal cooling performance.

Adjusting a TXV valve involves understanding its operating principle, identifying any issues or inefficiencies, and making necessary adjustments to the valve's settings. Proper adjustment of TXVs plays a crucial role in maintaining system efficiency, reducing energy consumption, and extending the system's lifespan.

In this article, we will explore the process of adjusting a TXV valve, discussing its importance, benefits, and common adjustment procedures. By understanding the principles and techniques involved, technicians and homeowners can optimize the performance of their refrigeration systems, ensuring proper cooling and energy efficiency.

- Zeinab Harake Boyfriend Who Is She Dating

- Tlc S I Love A Mama S

- Singer Sami Chokri And Case Update As

- Justin Bieber Sells Entire Music Catalogue For

- What Is Sonia Acevedo Doing Now Jamison

Can You Adjust A Txv Valve

Understanding the essential aspects of adjusting a TXV valve is crucial for optimizing the performance of refrigeration and air conditioning systems. These aspects encompass various dimensions, including the valve's operating principle, adjustment procedures, troubleshooting techniques, and the impact on system efficiency.

- Operating principle

- Superheat adjustment

- Subcooling adjustment

- Pressure-enthalpy diagram

- Valve capacity

- Refrigerant flow control

- System efficiency

- Energy consumption

- Troubleshooting

- Maintenance

By understanding these key aspects, technicians and homeowners can make informed decisions regarding TXV valve adjustment, ensuring proper system operation, enhanced cooling performance, and reduced energy consumption. Adjusting a TXV valve requires a thorough understanding of refrigeration principles, attention to detail, and proper adjustment techniques. Regular maintenance and timely adjustments can extend the lifespan of the system and contribute to overall energy efficiency.

Operating principle

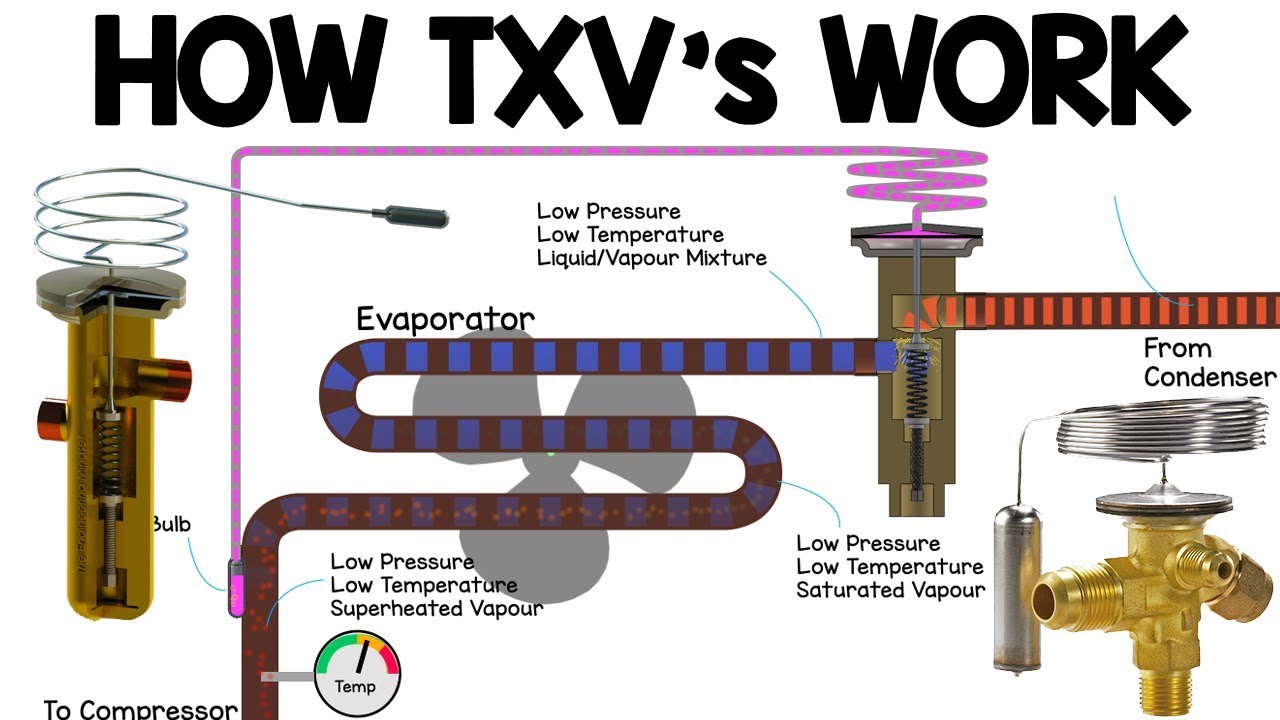

The operating principle of a thermal expansion valve (TXV) is a fundamental aspect of understanding how to adjust it effectively. TXVs are designed to control the flow of refrigerant in a refrigeration system based on the temperature of the evaporator. This is achieved through a combination of mechanical and thermodynamic principles.

- Tammy Camacho Obituary A Remarkable Life Remembered

- What Religion Is Daphne Oz And Is

- Is Shauntae Heard Fired From Her Job

- Meet Jason Weathers And Matthew Weathers Carl

- Did Tori Bowie Baby Survive What Happened

The TXV consists of a sensing bulb, capillary tube, and diaphragm assembly. The sensing bulb is attached to the evaporator outlet and contains a volatile liquid that expands or contracts in response to temperature changes. The capillary tube connects the sensing bulb to the diaphragm assembly, which is located within the TXV body. As the temperature of the evaporator changes, the pressure in the sensing bulb changes, causing the diaphragm to move. This movement adjusts the position of the valve seat, thereby regulating the flow of refrigerant through the TXV.

Understanding the operating principle of a TXV is critical for making informed adjustments. By manipulating the valve's settings, technicians can fine-tune the refrigerant flow to achieve optimal cooling performance and system efficiency. Proper adjustment of the TXV can prevent overfeeding or underfeeding of the evaporator, ensuring stable and efficient operation of the refrigeration system.

Superheat adjustment

Superheat adjustment is a critical component of adjusting a TXV valve. Superheat refers to the difference in temperature between the refrigerant's saturation temperature at the evaporator outlet and its actual temperature. Adjusting the superheat involves manipulating the TXV valve's settings to achieve the desired superheat value, typically between 5F and 15F (2.8C and 8.3C).

Proper superheat adjustment ensures optimal cooling performance and system efficiency. If the superheat is too low, the evaporator may flood with liquid refrigerant, reducing its heat transfer capacity and potentially causing compressor damage. Conversely, if the superheat is too high, the evaporator may not receive enough refrigerant, leading to reduced cooling capacity and increased energy consumption.

In practice, superheat adjustment is typically performed using a temperature gauge and a set of adjustment tools. By measuring the superheat at the evaporator outlet and comparing it to the desired value, technicians can adjust the TXV valve accordingly. This involves adjusting the valve's spring tension or adjusting the position of the sensing bulb to achieve the desired superheat setting.

Understanding the relationship between superheat adjustment and TXV valve adjustment is essential for optimizing the performance of refrigeration systems. Proper superheat adjustment ensures efficient and reliable operation, preventing potential issues such as evaporator flooding or insufficient cooling capacity. Regular monitoring and adjustment of superheat can contribute to increased energy savings and extended system lifespan.

Subcooling adjustment

Subcooling adjustment is another vital aspect of adjusting a TXV valve. Subcooling refers to the difference between the refrigerant's condensing temperature and its temperature at the TXV inlet. Proper subcooling adjustment ensures that the refrigerant enters the TXV in a subcooled state, preventing flash gas formation and ensuring stable valve operation.

Adjusting the subcooling involves manipulating the TXV valve's settings to achieve the desired subcooling value, typically between 5F and 15F (2.8C and 8.3C). Insufficient subcooling can lead to valve hunting, erratic operation, and reduced system efficiency. Excessive subcooling, on the other hand, can result in reduced evaporator capacity and increased energy consumption.

In practice, subcooling adjustment is often performed simultaneously with superheat adjustment. By monitoring both superheat and subcooling values, technicians can fine-tune the TXV valve to achieve optimal system performance. This involves adjusting the valve's spring tension, sensing bulb position, or refrigerant charge to obtain the desired subcooling setting.

Understanding the relationship between subcooling adjustment and TXV valve adjustment is essential for optimizing the performance of refrigeration systems. Proper subcooling adjustment ensures stable valve operation, prevents flash gas formation, and contributes to efficient and reliable system operation. Regular monitoring and adjustment of both superheat and subcooling can lead to increased energy savings, extended system lifespan, and improved cooling performance.

Pressure-enthalpy diagram

In the context of adjusting a TXV valve, understanding the pressure-enthalpy diagram is crucial. This diagram graphically represents the thermodynamic properties of a refrigerant and provides valuable insights into the system's behavior.

- Pressure-enthalpy curve

The pressure-enthalpy curve on the diagram represents the relationship between pressure and enthalpy for a specific refrigerant. This curve serves as a reference for determining the refrigerant's state and properties at different conditions.

- Constant temperature lines

Constant temperature lines are horizontal lines on the diagram that represent different temperatures. These lines help visualize the change in enthalpy as the refrigerant undergoes a change in pressure at a constant temperature.

- Saturation dome

The saturation dome on the diagram is a region bounded by two constant temperature lines and represents the two-phase region where the refrigerant exists as a mixture of liquid and vapor. The saturation dome provides information about the refrigerant's saturation properties.

- Critical point

The critical point on the diagram is the point where the liquid and vapor phases of the refrigerant become indistinguishable. Beyond this point, the refrigerant exists as a supercritical fluid.

The pressure-enthalpy diagram serves as a valuable tool for analyzing and adjusting TXV valves. By understanding the refrigerant's behavior and properties through this diagram, technicians can make informed decisions regarding valve adjustments to optimize system performance, enhance energy efficiency, and ensure reliable operation.

Valve capacity

Understanding valve capacity is essential when adjusting a TXV valve. Valve capacity refers to the maximum flow rate that a valve can handle under specified operating conditions. It is a critical factor in determining the proper valve size for a given application and ensuring optimal system performance.

- Flow coefficient (Cv)

Cv is a measure of the valve's flow capacity and is determined by the valve's design and construction. A higher Cv indicates a higher flow capacity.

- Pressure drop

Pressure drop is the difference in pressure between the inlet and outlet of the valve. It is affected by the flow rate, valve design, and refrigerant properties.

- Valve sizing

Proper valve sizing is crucial to ensure that the valve can meet the required flow demand without excessive pressure drop or cavitation.

- System performance

Valve capacity directly impacts system performance. An undersized valve can restrict flow and reduce cooling capacity, while an oversized valve can lead to excessive pressure drop and energy waste.

By carefully considering valve capacity and its components, technicians can select and adjust TXV valves to match the specific requirements of the refrigeration system. This ensures optimal flow control, efficient operation, and reliable performance over the system's lifetime.

Refrigerant flow control

Refrigerant flow control is a crucial aspect of adjusting a TXV valve, as it directly impacts the performance and efficiency of the refrigeration system. By manipulating the refrigerant flow, technicians can optimize cooling capacity, reduce energy consumption, and ensure system reliability.

- Valve opening

The TXV valve regulates refrigerant flow by adjusting its opening. A wider valve opening allows more refrigerant to flow, increasing cooling capacity. Conversely, a narrower opening restricts flow, reducing capacity.

- Sensing bulb placement

The position of the sensing bulb, which monitors evaporator temperature, influences refrigerant flow. Placing the bulb closer to the evaporator outlet results in higher superheat and reduced refrigerant flow. Conversely, placing it further away leads to lower superheat and increased flow.

- Refrigerant charge

The amount of refrigerant in the system affects refrigerant flow. An excessive charge can lead to flooding and reduced flow, while an insufficient charge can cause starvation and reduced cooling capacity.

- System demand

The cooling demand of the system influences refrigerant flow. Higher demand requires increased flow, which can be achieved by adjusting the TXV valve accordingly.

Understanding and controlling refrigerant flow through the TXV valve is essential for optimizing system performance. By considering these factors and making informed adjustments, technicians can ensure efficient and reliable operation of refrigeration systems.

System efficiency

System efficiency is a critical component of adjusting a TXV valve, as it directly impacts the overall performance and energy consumption of a refrigeration system. A well-adjusted TXV valve ensures optimal refrigerant flow, leading to efficient cooling and reduced operating costs.

The connection between system efficiency and TXV valve adjustment lies in the valve's ability to regulate refrigerant flow based on the evaporator's temperature. By fine-tuning the valve's settings, technicians can achieve the desired superheat and subcooling values, optimizing the system's thermodynamic cycle. This precise control of refrigerant flow prevents overfeeding or underfeeding of the evaporator, reducing energy waste and ensuring stable cooling performance.

In real-life applications, adjusting a TXV valve for improved system efficiency can translate into significant savings. For instance, in a commercial refrigeration system, a properly adjusted TXV valve can reduce energy consumption by up to 15%, leading to lower utility bills and a reduced carbon footprint. Additionally, optimized system efficiency can extend the lifespan of the refrigeration equipment, minimizing maintenance costs and downtime.

Understanding the relationship between system efficiency and TXV valve adjustment is essential for technicians and facility managers seeking to optimize the performance of their refrigeration systems. By carefully adjusting the TXV valve and monitoring system parameters, they can ensure efficient operation, reduce energy consumption, and enhance the overall reliability of their cooling systems.

Energy consumption

Energy consumption is an integral component of adjusting a TXV valve, as it directly impacts the overall efficiency of a refrigeration system. A properly adjusted TXV valve can significantly reduce energy consumption by optimizing refrigerant flow and maintaining desired superheat and subcooling values. This precise control of refrigerant flow prevents overfeeding or underfeeding of the evaporator, reducing energy waste and ensuring stable cooling performance.

In real-life applications, the impact of TXV valve adjustment on energy consumption is substantial. For instance, in a commercial refrigeration system, a poorly adjusted TXV valve can lead to energy losses of up to 20%. By contrast, a well-adjusted TXV valve can reduce energy consumption by up to 15%, resulting in lower utility bills and a reduced carbon footprint.

Practical applications of this understanding include regular maintenance and monitoring of TXV valves in refrigeration systems. Technicians and facility managers should prioritize timely adjustments and fine-tuning of TXV valves to ensure optimal energy efficiency. Additionally, advanced control systems can be employed to continuously monitor and adjust TXV valves based on real-time operating conditions, further enhancing energy savings.

Troubleshooting

Troubleshooting is an essential component of adjusting a TXV valve, as it helps identify and rectify issues that may affect the valve's performance and the overall efficiency of the refrigeration system. Troubleshooting involves a systematic approach to identify the root cause of a problem and implement appropriate solutions.

In the context of TXV valves, troubleshooting may involve checking for common problems such as incorrect valve sizing, improper sensing bulb placement, refrigerant leaks, or blockages in the refrigerant lines. By carefully examining these aspects, technicians can pinpoint the source of the issue and make necessary adjustments to the TXV valve to restore optimal operation.

Real-life examples of troubleshooting in TXV valve adjustment include situations where the system is experiencing poor cooling performance, excessive energy consumption, or erratic temperature control. In such cases, troubleshooting involves analyzing system parameters, monitoring refrigerant flow, and inspecting the TXV valve components to identify any deviations from the desired operating conditions. Once the issue is identified, appropriate adjustments can be made to the TXV valve, such as fine-tuning the superheat or subcooling settings, replacing worn components, or addressing refrigerant leaks, to restore the system's efficiency and performance.

Understanding the connection between troubleshooting and TXV valve adjustment is crucial for technicians and facility managers responsible for maintaining refrigeration systems. By recognizing the importance of troubleshooting and applying systematic approaches to problem identification and resolution, they can ensure that TXV valves are functioning optimally, leading to improved system efficiency, reduced energy consumption, and enhanced cooling performance.

Maintenance

Maintenance is an imperative component of adjusting a TXV valve, as it directly influences the valve's performance and the overall efficiency of the refrigeration system. Regular maintenance practices ensure that the TXV valve is operating within optimal parameters, preventing potential issues and maintaining desired cooling conditions.

The connection between maintenance and TXV valve adjustment lies in the valve's sensitivity to changes in operating conditions and refrigerant flow. Over time, dirt, debris, or wear can accumulate within the valve, affecting its ability to regulate refrigerant flow accurately. Regular maintenance, including cleaning, inspection, and component replacement, helps prevent these issues and ensures the valve's continued precision.

In real-life applications, maintenance plays a critical role in optimizing TXV valve performance. For instance, in a supermarket refrigeration system, neglecting maintenance can lead to a gradual decrease in cooling efficiency and increased energy consumption. Conversely, a well-maintained TXV valve ensures stable temperature control, reduces energy waste, and prolongs the system's lifespan.

Understanding the relationship between maintenance and TXV valve adjustment is crucial for technicians and facility managers responsible for maintaining refrigeration systems. By prioritizing regular maintenance and adhering to manufacturer guidelines, they can ensure that TXV valves are operating optimally, leading to improved system efficiency, reduced energy consumption, and enhanced cooling performance.

Frequently Asked Questions

This section addresses common queries and concerns regarding the adjustment of TXV valves, providing concise and informative answers to guide readers.

Question 1: Why is adjusting a TXV valve important?

Answer: Adjusting a TXV valve optimizes refrigerant flow in a refrigeration system, ensuring efficient operation, reduced energy consumption, and enhanced cooling performance.

Question 2: What are the key aspects to consider when adjusting a TXV valve?

Answer: Superheat, subcooling, valve capacity, refrigerant flow control, system efficiency, and energy consumption are crucial aspects that influence TXV valve adjustment.

Question 3: How do I adjust the superheat of a TXV valve?

Answer: Superheat adjustment involves manipulating the valve's spring tension or sensing bulb position to achieve the desired superheat value, typically between 5F and 15F (2.8C and 8.3C).

Question 4: What impact does a properly adjusted TXV valve have on the energy consumption of a refrigeration system?

Answer: A well-adjusted TXV valve reduces energy consumption by optimizing refrigerant flow, minimizing overfeeding or underfeeding of the evaporator, and maintaining desired superheat and subcooling values.

Question 5: How often should I check and adjust my TXV valve?

Answer: Regular maintenance and inspection are crucial to ensure optimal TXV valve performance. The frequency of adjustments depends on the operating conditions and system usage.

Question 6: What are the consequences of neglecting TXV valve maintenance?

Answer: Neglecting TXV valve maintenance can lead to reduced cooling efficiency, increased energy consumption, premature system failure, and potential safety hazards.

These FAQs provide essential insights into the importance, considerations, and procedures involved in adjusting a TXV valve. Understanding these aspects empowers technicians and homeowners to optimize their refrigeration systems for efficient operation, reduced energy consumption, and enhanced cooling performance.

Moving forward, the next section will delve deeper into the practical steps and techniques for adjusting a TXV valve, providing a comprehensive guide to ensure proper system performance and longevity.

Tips for Adjusting a TXV Valve

This section provides a set of practical tips to guide technicians and homeowners in adjusting TXV valves for optimal refrigeration system performance and energy efficiency.

Tip 1: Determine System Requirements: Before adjusting the TXV valve, determine the desired superheat and subcooling values based on the specific refrigerant and system operating conditions.

Tip 2: Use Precision Tools and Gauges: Ensure accurate measurements and adjustments by using calibrated gauges and tools specifically designed for refrigeration systems.

Tip 3: Monitor System Parameters: Continuously monitor system parameters such as refrigerant pressure, temperature, and flow rate to assess the valve's performance and make necessary adjustments.

Tip 4: Check for Leaks and Blockages: Inspect the entire refrigerant circuit for leaks or blockages that could affect refrigerant flow and valve operation.

Tip 5: Adjust Superheat First: Begin by adjusting the superheat to the desired value. This directly impacts the refrigerant flow rate into the evaporator.

Tip 6: Fine-tune Subcooling: Once superheat is set, adjust the subcooling to optimize valve operation and prevent liquid refrigerant from entering the compressor.

Tip 7: Consider System Load: Account for varying system load conditions and adjust the TXV valve accordingly to maintain optimal cooling performance.

Tip 8: Regular Maintenance and Monitoring: Schedule regular maintenance and monitoring to ensure the TXV valve continues to operate efficiently and make timely adjustments as needed.

By following these tips, technicians and homeowners can effectively adjust TXV valves, leading to improved system efficiency, reduced energy consumption, and enhanced cooling performance.

In the concluding section, we will discuss the importance of troubleshooting and ongoing maintenance to ensure the longevity and optimal performance of the adjusted TXV valve.

Conclusion

Adjusting a TXV valve involves understanding its operating principle, superheat and subcooling adjustment, valve capacity, refrigerant flow control, system efficiency, and energy consumption. By considering these factors, technicians can optimize TXV valve performance, leading to improved cooling, reduced energy consumption, and enhanced system reliability.

The key takeaways from this exploration of "Can You Adjust A Txv Valve" are:

- Proper TXV valve adjustment is crucial for efficient and reliable refrigeration system operation.

- Understanding the interconnections between superheat, subcooling, valve capacity, and refrigerant flow is essential for effective adjustment.

- Regular maintenance and troubleshooting ensure the ongoing performance and longevity of the adjusted TXV valve.

Adjusting a TXV valve is a critical aspect of refrigeration system maintenance and optimization. By embracing a proactive approach to valve adjustment and system monitoring, technicians and homeowners can ensure maximum cooling performance, energy efficiency, and system longevity.

- Noah Pc3a9rez Chris Perez Son Age

- Who Is Hunter Brody What Happened To

- Meet Ezer Billie White The Daughter Of

- Simona Halep Early Life Career Husband Net

- Malachi Barton S Dating Life Girlfriend Rumors

How To Install The Thermal Expansion Valve(TXV) Lando Water Chillers

When and How to Adjust a Thermostatic Expansion Valve (TXV) techtown

cost to replace expansion valve on ac unit rusert