Your Ideas In Hand: Exploring The 3D Printing Service Sculpteo

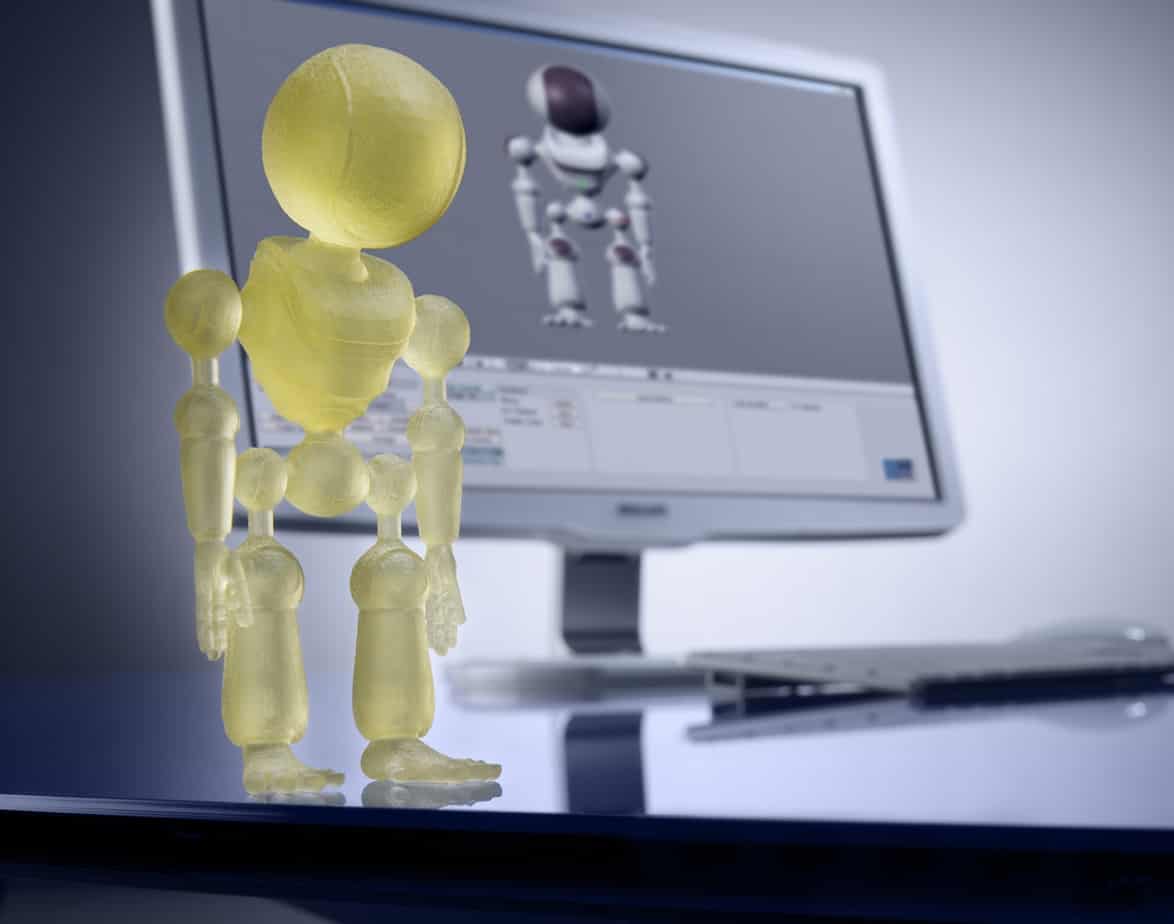

Have you ever dreamed of bringing your digital creations into the physical world? It's a pretty cool thought, isn't it? For many, the step from a design on a screen to an object you can hold can seem like a big leap. That's where a fantastic solution like a 3D printing service comes into play, helping bridge that gap. We're talking about making those imaginative ideas real, in a way that feels accessible and exciting.

Think about it: with a community of over one million creators, we are the world’s largest platform to publish, share, and discover 3D content on web, mobile, AR, and VR. That means a whole lot of amazing digital stuff is out there. From product models to printable parts, 3D design is the first step in making big ideas real. You've got these incredible visions, and you know, sometimes you just want to touch them, right?

This is where a service like Sculpteo steps in, offering a way to turn those digital blueprints into tangible items. They offer a direct path from your computer screen to a finished piece, letting you explore what's possible. So, if you're curious about how a 3D printing service Sculpteo can help you, keep reading.

- Legendary Rella S Relationship Status Is She

- How To Make Water Breathing Potion In

- Eve Wembanyama Parents Meet Fc3a9lix Wembanyama

- Know About Camren Bicondova Age Height Gotham

- Benoni Woman Shows R4 000 Grocery Haul

Table of Contents

- What is a 3D Printing Service and Why Use Sculpteo?

- Bringing Your Designs to Life: The Sculpteo Process

- Who Benefits Most from Sculpteo's Offerings?

- The Sculpteo Advantage: What Makes It Stand Out?

- Tips for a Great 3D Printing Experience

- Common Questions About 3D Printing with Sculpteo

- The Future of Making: How Sculpteo Fits In

What is a 3D Printing Service and Why Use Sculpteo?

A 3D printing service is, essentially, a company that owns and operates industrial-grade 3D printers, making them available for others to use. This means you don't need to buy a big, expensive machine yourself, or learn all the ins and outs of operating one. It's like having access to a high-tech workshop without the overhead, which is pretty handy for many people.

For many creators, the cost of owning a 3D printer can be a real hurdle, not to mention the technical know-how needed to get good results. Plus, personal printers often have limited material options, so you might not be able to print with metal or certain durable plastics. A service gets around all these issues, allowing you to focus on your design work.

Sculpteo stands out as a significant player in this area, offering a wide array of services. They help you turn your digital files into physical objects, no matter how complex. It's almost like they say, "If you can dream it, you can build it," which is a really powerful idea for anyone creating something new.

- Meet Maya Erskine S Parents Mutsuko Erskine

- Is Shauntae Heard Fired From Her Job

- Zeinab Harake Boyfriend Who Is She Dating

- Tammy Camacho Obituary A Remarkable Life Remembered

- Who Is Hunter Brody What Happened To

They handle the tough parts, like choosing the right machine for your specific material and ensuring the print comes out looking just right. This allows designers and innovators to simply upload their files and receive their finished pieces, saving a lot of time and effort. So, you know, it just makes things simpler.

Bringing Your Designs to Life: The Sculpteo Process

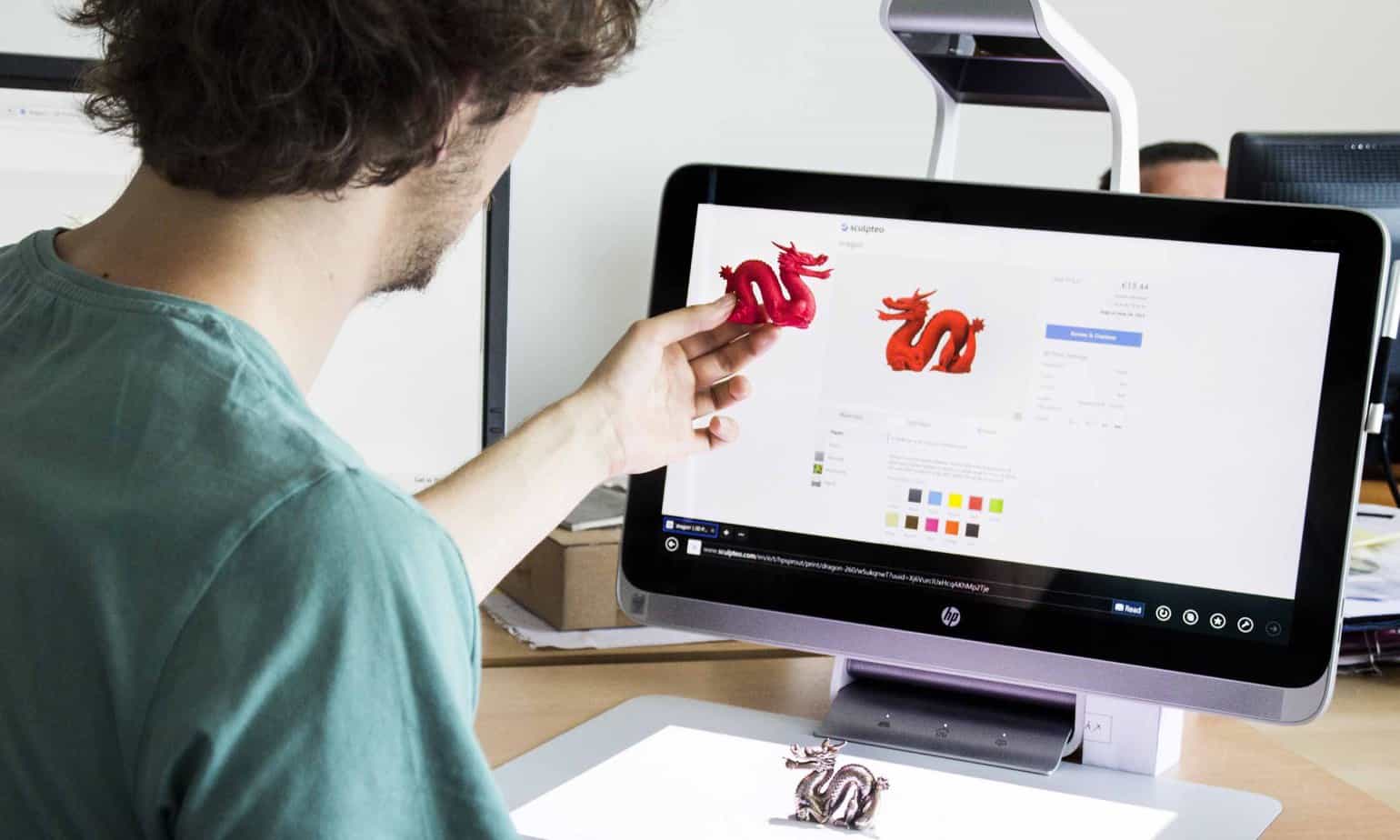

Getting your design printed with a service like Sculpteo follows a pretty straightforward path, actually. It starts with your idea, moves through the digital design phase, and then transitions into the actual manufacturing. This whole process is designed to be as smooth as possible for you.

Uploading Your Model

The first step, naturally, is having your 3D design ready. There are many ways to create these designs. Programs like SketchUp enable you to design, define, and plan in all stages of the project, which is very helpful. It’s like, the most intuitive way to design, document, and communicate your ideas in 3D.

You can work through your ideas in 3D space using tools such as Figuro, a free online 3D modeling website for students, 3D hobbyists, artists, game developers, and more. Use Figuro to create 3D models quickly and easily, you know. Tinkercad is a free web app for 3D design, electronics, and coding, trusted by over 75 million people around the world, offering another great option.

Sketchup Free is the simplest free 3D modeling software on the web — no strings attached, so it’s pretty accessible. You can also find an extensive library of 3D meshes; you can find all basic and less basic shapes from Sumo3D so you can start building your world with them. Once your model is ready, you simply upload it to the Sculpteo platform. This online 3D editor to build and print 3D models integrates with the Sumo library to add models, images, sounds, and textures from other apps, giving you many choices.

Choosing Your Materials

Once your model is uploaded, the next big decision is what material you want your object made from. Sculpteo offers a wide selection, from various plastics like nylon and resin to different metals such as aluminum and steel. Each material has its own unique properties, making it suitable for different uses.

For example, if you need something strong and light for a prototype, a certain type of plastic might be best. If you're making a functional part that needs to withstand heat, a metal could be the right choice. They provide detailed information on each material, helping you pick the perfect one for your project, which is quite helpful.

The material choice also affects the final look and feel of your object. You can even add colors and textures to make it your own masterpiece, which is a nice touch. This step is pretty important because it directly influences how your finished product will perform and appear.

Getting Your Part Made

After you've picked your material and finalized your order, Sculpteo takes over. Their expert teams prepare your file for printing, ensuring everything is set up correctly for their industrial machines. This involves checking for any potential issues that might arise during the printing process.

The actual printing happens in their facilities, using advanced 3D printing technologies. Depending on the material and complexity of your design, this can take a bit of time. Once printed, your object often goes through a finishing process, which might include cleaning, polishing, or adding coatings.

They have quality checks at various stages to make sure the final product meets high standards. Then, your custom-made part is carefully packaged and shipped right to your door. It’s a very streamlined process, really.

Who Benefits Most from Sculpteo's Offerings?

Many different kinds of people and groups find real value in using a 3D printing service like Sculpteo. It's not just for big companies or tech gurus; it's pretty much for anyone with an idea they want to bring to life in three dimensions. So, you know, it has broad appeal.

Creators and Hobbyists

If you're someone who loves to create, whether it's for fun or as part of a personal project, Sculpteo can be a game-changer. Think about all the amazing 3D content out there. You can download millions of 3D models and files for your 3D printer, laser cutter, or CNC. From custom parts to unique designs, you can find them on Thingiverse.

Many free and accessible tools exist for design, too. SketchUp Free is the simplest free 3D modeling software on the web — no strings attached, making it easy to get started. Tinkercad, trusted by over 75 million people around the world, is another great option for beginners and hobbyists. With nothing more than an iPad, Tinkercad makes it easy to turn your designs into augmented reality (AR) experiences, which is pretty cool.

For those who enjoy sharing their work, you can share your models and get inspired with the world’s largest 3D model library. A service like Sculpteo lets these creators turn their digital files, perhaps a custom figurine or a unique piece of jewelry, into something they can hold, paint, or give as a gift, without needing to buy their own printer. It’s quite liberating, actually.

Product Developers and Businesses

For businesses and product developers, Sculpteo offers significant advantages, especially when it comes to prototyping and small-batch manufacturing. From product models to printable parts, 3D design is the first step in making big ideas real. Instead of investing heavily in manufacturing equipment for early-stage development, they can simply send their designs to Sculpteo.

This allows for rapid iteration. A company can design a new part, have a prototype printed quickly, test it, make changes, and then print another version, all in a much shorter timeframe than traditional manufacturing methods. This speeds up the development cycle considerably, you know.

For small production runs or custom components, Sculpteo also provides a cost-effective solution. They don't need to commit to large minimum order quantities, which is often a requirement with traditional factories. This flexibility is very valuable for startups and businesses needing specialized parts without massive upfront costs.

The Sculpteo Advantage: What Makes It Stand Out?

Sculpteo has built a strong reputation in the 3D printing world for several reasons. One major point is their commitment to quality. They use high-end industrial machines and have a team that understands the nuances of different printing technologies and materials. This means you can generally expect a good outcome for your printed objects.

Their wide range of materials is another big plus. As mentioned, they offer everything from robust plastics to various metals, allowing users to pick the best fit for their project's needs. This variety means they can cater to a very broad spectrum of applications, which is quite useful.

The user experience on their platform is also designed to be straightforward. You can bring your 3D design online, and have your SketchUp projects with you wherever you go, which speaks to their accessibility. The process of uploading a model, getting an instant quote, and choosing options is pretty intuitive, making it easy even for those new to 3D printing services.

They also provide support and guidance, helping users understand the best practices for preparing their files and selecting materials. This expertise adds a layer of trustworthiness, as you feel you're getting advice from people who really know what they're doing. It’s pretty reassuring, honestly.

Tips for a Great 3D Printing Experience

To get the best results when using a 3D printing service like Sculpteo, there are a few things you can do. First off, really pay attention to your 3D model's file preparation. Make sure your design is "watertight," meaning it has no holes or gaps in its surfaces. This helps the printer understand exactly what it needs to build, and avoids potential errors.

Secondly, spend some time understanding the material properties. Each material has different strengths, flexibilities, and surface finishes. If your part needs to be flexible, choosing a rigid plastic might not work out well, for example. Sculpteo provides detailed guides on their materials, which are very helpful resources.

Also, it's a good idea to check their design guidelines for each specific material and printing technology. These guidelines often specify minimum wall thicknesses, detail sizes, and other important considerations. Following these can prevent issues and ensure your part prints successfully, which saves you time and money, too.

Finally, don't be afraid to start with a simpler design if you're new to this. You can always work your way up to more complex projects. Getting a feel for the process with something less intricate can build your confidence and help you understand the capabilities of 3D printing, which is actually a pretty good approach.

Common Questions About 3D Printing with Sculpteo

People often have similar questions when they first consider using a 3D printing service Sculpteo. We'll try to answer a few of the common ones here, which might help clear things up for you.

What materials can Sculpteo 3D print? Sculpteo offers a wide selection of materials, including various plastics (like Polyamide, resins, and flexible materials), metals (such as Aluminum, Stainless Steel, and Titanium), and even some ceramics. The exact list can change a bit over time as technology improves, but they generally provide options suitable for many different applications, from prototypes to functional parts. You can always check their website for the most current offerings, you know.

How much does Sculpteo 3D printing cost? The cost of 3D printing with Sculpteo depends on several factors. These include the size and complexity of your 3D model, the material you choose, and the finishing options you select. Generally, larger objects, more intricate designs, and premium materials will cost more. They usually provide an instant quote tool on their platform once you upload your model, so you can get a precise price before you commit, which is really convenient.

Is Sculpteo good for prototyping? Absolutely, Sculpteo is very good for prototyping. Their service allows designers and businesses to quickly create physical versions of their ideas. This speed helps in testing designs, identifying flaws, and making quick adjustments without the need for expensive tooling or long lead times associated with traditional manufacturing. It’s a pretty efficient way to develop new products, honestly.

The Future of Making: How Sculpteo Fits In

The world of 3D creation is always moving forward, and services like Sculpteo are a big part of that progress. They make advanced manufacturing accessible to everyone, not just large corporations. This means more people can turn their ideas into reality, which could lead to all sorts of cool new things.

With nothing more than an iPad, Tinkercad makes it easy to turn your designs into augmented reality (AR) experiences, showing how digital and physical worlds are blending. Services like Sculpteo provide the bridge to make those AR designs tangible, if you wish. This connection between digital tools and physical output is a key part of how things will be made in the future.

As 3D modeling tools become even more intuitive, and as materials and printing technologies advance, the possibilities will just keep growing. You can add colors and textures to make it your own masterpiece, and then have it printed exactly as you imagined. Sculpteo, and similar services, are helping to shape a future where custom creation is pretty much the norm, not the exception.

They are, in a way, democratizing manufacturing, giving more people the chance to innovate and build. This ongoing trend suggests a very exciting time ahead for anyone interested in making things.

So, if you're ready to see your designs take shape, exploring a 3D printing service Sculpteo could be your next step. Learn more about 3D printing on our site, and check out this external reference for more details on their offerings. We also have information on 3D modeling software to help you get started with your designs.

- Beloved Irish Father Clinton Mccormack Dies After

- Joe Kennedy Iii Religion Meet His Parents

- Thomas Lineberger Aberdeen Nc Famous Internal Medicine

- Who Is Jahira Dar Who Became Engaged

- Zeinab Harake Boyfriend Who Is She Dating

Sculpteo vs Shapeways: Which 3D Printing Service is Right for You

Sculpteo vs Shapeways: Which 3D Printing Service is Right for You

The Best 3D Printing Services Online in 2023 | All3DP