Best Power Driven Diesel [For Sale!]

Equipment employing a diesel engine as its primary source of mechanical force constitutes a significant category. These systems leverage the combustion of diesel fuel to generate rotational or linear motion, effectively powering a wide array of machinery. A concrete mixer, for example, may utilize this method for turning its mixing drum, while heavy construction vehicles rely on it for locomotion and the operation of hydraulic systems.

The utilization of compression-ignition engines offers numerous advantages in various sectors. This technology provides considerable torque and power output, making it suitable for demanding applications in construction, agriculture, and transportation. Furthermore, compression-ignition engines have evolved to increase fuel efficiency, reducing operational costs. Throughout history, they have proven to be reliable and durable, cementing their role as a fundamental power source across industries.

The subsequent sections will delve into specific applications of this technology, focusing on key areas such as generators, pumps, and specialized vehicles. Further exploration will investigate advancements in the technology, addressing environmental impact and examining the future direction of the field.

- How To Make Water Breathing Potion In

- Noah Pc3a9rez Chris Perez Son Age

- Singer Sami Chokri And Case Update As

- Janice Huff And Husband Warren Dowdy Had

- Milo Ventimiglia Reportedly Dating New Girlfriend Jarah

Frequently Asked Questions Regarding Diesel-Powered Systems

This section addresses common inquiries related to machinery utilizing diesel engines as their primary power source. The objective is to provide clarity and factual information concerning their operation, maintenance, and applicability.

Question 1: What are the primary applications for diesel-powered equipment?

Diesel engines are widely employed in heavy machinery, generators, pumps, and transportation vehicles. Their robust design and high torque output make them suitable for demanding tasks across various industries, including construction, agriculture, mining, and logistics.

- Wwe Billy Graham Illness Before Death Was

- Where Was I Want You Back Filmed

- Claudia Sampedro Wags Miami Age Engaged Husband

- Jasprit Bumrah Injury Update What Happened To

- Thomas Lineberger Aberdeen Nc Famous Internal Medicine

Question 2: How does a diesel engine differ from a gasoline engine?

Diesel engines utilize compression ignition, where air is compressed to a high ratio, raising its temperature. Fuel is then injected, igniting spontaneously. Gasoline engines rely on spark ignition to ignite the air-fuel mixture.

Question 3: What are the typical maintenance requirements for diesel equipment?

Regular maintenance includes oil changes, filter replacements (air, fuel, oil), coolant checks, and inspection of belts and hoses. Specific maintenance schedules vary depending on the equipment type and operating conditions.

Question 4: What are some common issues that can arise with diesel machinery?

Potential problems include fuel injector issues, clogged filters, overheating, and starting difficulties. Regular maintenance and proper fuel management are essential to mitigate these risks.

Question 5: Are there environmental considerations associated with the operation of diesel engines?

Diesel engines can produce emissions such as particulate matter and nitrogen oxides. However, advancements in engine technology and the use of cleaner fuels are helping to reduce their environmental impact.

Question 6: What is the expected lifespan of diesel-powered equipment?

With proper maintenance and operation, diesel engines can have a long service life, often exceeding thousands of hours. Regular inspections and adherence to recommended maintenance schedules are critical for maximizing longevity.

In summary, understanding the operational principles, maintenance requirements, and potential environmental impacts is crucial for effectively utilizing diesel-powered systems. These systems remain a vital part of modern infrastructure and industry.

The following section will explore the specific types of machinery that commonly utilize this technology, with detailed breakdowns of their applications and performance characteristics.

Optimizing the Use of Diesel-Powered Equipment

This section provides essential guidance for maximizing the efficiency, longevity, and safety of equipment utilizing diesel engines as the primary power source. Adhering to these principles promotes operational excellence and minimizes downtime.

Tip 1: Employ Proper Fuel Storage Protocols. Contamination of diesel fuel is a frequent cause of engine malfunction. Utilize clean, designated containers and adhere to established procedures for fuel handling and storage to prevent the introduction of water, sediment, or other contaminants.

Tip 2: Adhere Strictly to Recommended Maintenance Schedules. Preventative maintenance is critical to ensuring optimal performance and extending the lifespan of equipment. Diligently follow the manufacturer's specified maintenance intervals for oil changes, filter replacements, and other essential services.

Tip 3: Conduct Regular Inspections of Critical Components. Routine visual inspections of hoses, belts, fluid levels, and other critical components can identify potential issues before they escalate into major problems. Promptly address any signs of wear, leakage, or damage.

Tip 4: Ensure Adequate Cooling System Function. Overheating can cause severe damage to diesel engines. Regularly check coolant levels, inspect radiator fins for obstructions, and verify the proper operation of cooling fans to maintain optimal engine temperature.

Tip 5: Properly Train Operators. Competent operation is paramount to the safe and efficient use of equipment. Provide operators with comprehensive training on equipment operation, safety procedures, and basic troubleshooting techniques.

Tip 6: Monitor Exhaust Emissions. Changes in exhaust color or the presence of excessive smoke can indicate underlying engine problems. Investigate any abnormal emissions and take corrective action promptly to prevent further damage and ensure compliance with environmental regulations.

Tip 7: Maintain Detailed Records. Comprehensive documentation of maintenance activities, repairs, and fuel consumption patterns can provide valuable insights into equipment performance and inform preventative maintenance strategies.

Following these recommendations enhances the reliability, safety, and economic viability of operating machinery utilizing diesel engines, minimizing unexpected downtime and maximizing the return on investment.

The concluding section will summarize the key aspects discussed throughout this article, reiterating the significance and lasting impact of this crucial power source in diverse applications.

Conclusion

The preceding discussion has explored the operational characteristics, maintenance considerations, and optimization strategies associated with power driven diesel systems. These systems, characterized by their reliance on diesel engines as primary movers, remain foundational across various industries due to their inherent power, durability, and relative efficiency. The breadth of application, from construction equipment and agricultural machinery to power generation and transportation, underscores the continued importance of this technology.

Despite ongoing advancements in alternative energy sources, power driven diesel continues to be an integral component of global infrastructure. Responsible management, proactive maintenance, and a commitment to embracing technological improvements focused on emissions reduction will be vital to maximizing the utility and minimizing the environmental impact of these systems in the decades to come. Further research and development remain critical to ensuring the long-term viability of this established power source.

- Where Was I Want You Back Filmed

- Mzansi Man Documents Sa Potholes Viral Tiktok

- What Is Sonia Acevedo Doing Now Jamison

- Who Is Miranda Rae Mayo Partner Her

- Layke Leischner Car Accident Resident Of Laurel

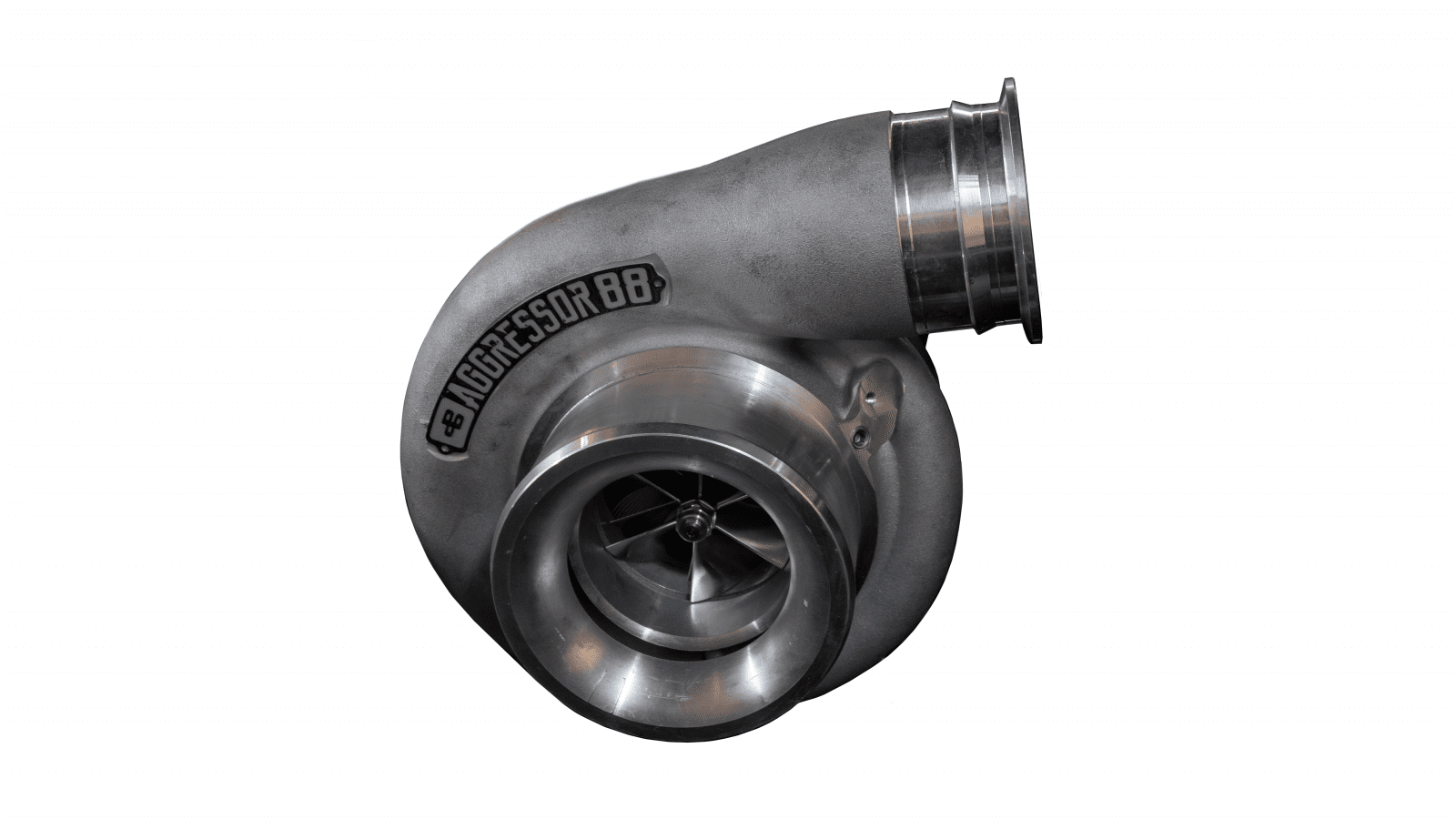

Power Driven Diesel Aggressor 62 Turbocharger Power Driven Diesel

Power Driven Diesel Aggressor 88 Power Driven Diesel

Products from Power Driven Diesel Power Driven Diesel